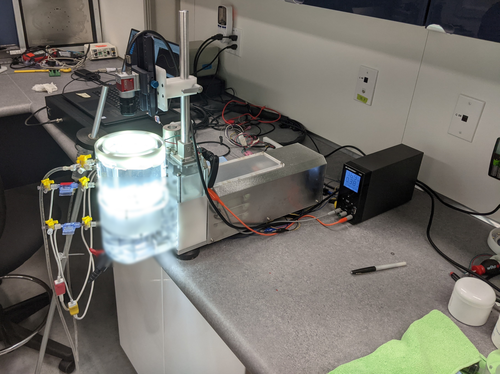

- While improving our thrust testing setup, we decided to evaluate how peak thrust for a given test speed is determined

- It was found that an average thrust from a successful pass provides a more representative peak thrust value than the minimum thrust from a successful pass given cyclical thrust fluctuations

- It was also found that the LRT Thrust Tester provided less thrust fluctuation than the LST Thrust tester, essentially eliminating larger thrust oscillations

- It's recommended that the testing team continue to log high speed thrust passes to gather more data and investigate any odd fluctuations further

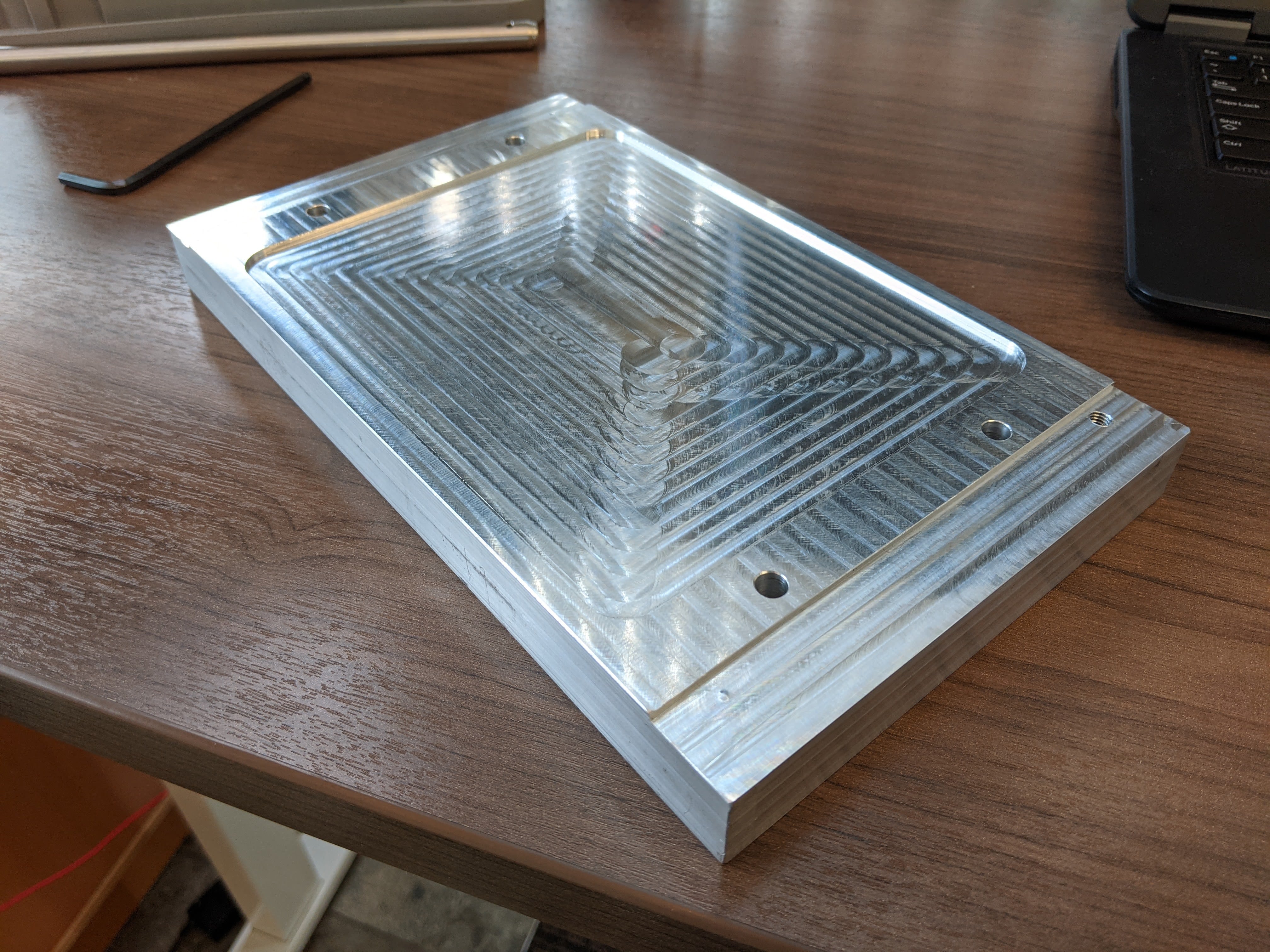

2019 Competition Car - UV19

UV19 was the last car to be built before COVID-19 lockdowns and was one of the most ambitious builds in the team's recent history. Having switched wheel sizes and engine platforms, the only part that was not redesigned for the 2019 season was the steering wheel.